Materials used for clothing

ACD Membrane - Clothing - Tents - Sleeping bags - Backpacks - Gelanots

It is a registered trademark of a unique membrane from a renowned Japanese manufacturer. Pinguin has more than 10 years of experience with its parameters, functionality and durability, which confirms the correctness of our decision to continue using this now traditional and proven product for Pinguin waterproof clothing under new commercial terms and under the new trademark A.C.D. (All Climate Dry) membrane.

A material that breathes. The A.C.D. membrane has no pores, which makes it fundamentally different from conventional microporous membranes. Nevertheless, the ability to let evaporated sweat through (breathe out) is second to none. This is due to the microstructure of the membrane made of a special polyurethane (PU) whose molecular structure and the mutual forces between PU and water molecules are optimal for this function. During physical exertion, a person heats up, sweats and the vapour concentration under his clothing increases. When a water vapour molecule gets close to the A.C.D. membrane, it is drawn between the PU molecules and becomes temporarily part of the membrane (i.e. the membrane is hydrophilic). Due to the higher temperature and water vapour concentration inside the garment, evaporated sweat is continuously forced through the membrane. This is as natural a phenomenon as water flowing from a higher place to a lower place.

Waterproof and windproof. The micropores of conventional membranes expand over time in stressed areas and let water through. Non-porous A.C.D. However, the membrane retains sufficient resistance to water pressure even after years of use. 100% wind resistance is essential to maintain the microclimate and thermal comfort of the user.

Durability and maintenance. A typical malady of conventional membranes is the gradual clogging of pores and thus deteriorating vapour permeability. Salts and fats contained in sweat, dirt and detergents can settle in the pores and clog them. A.C.D. Membrane does not suffer from this. It can be washed in the washing machine and with normal detergents, and can be gently tumble dried and ironed. It is not advisable to use only fabric softener, after washing it is recommended not to twist or wring the clothes, just let them drip.

It is a very lightweight membrane material made with a special technology where the membrane on the reverse side of the fabric is so resistant to mechanical damage that it does not need to be protected by a lining.

It is designed to produce lightweight and very packable garments that we can always have with us in case of bad weather.

It is a hydrophilic membrane that is laminated to the outer textile material of the sportswear. It forms a perfect protection against the weather and at the same time maintains a constant microclimate on the surface of the body at rest even during intense physical exertion.

It has been developed for active outdoor sports and its parameters satisfy even the most demanding comfort requirements of the user.

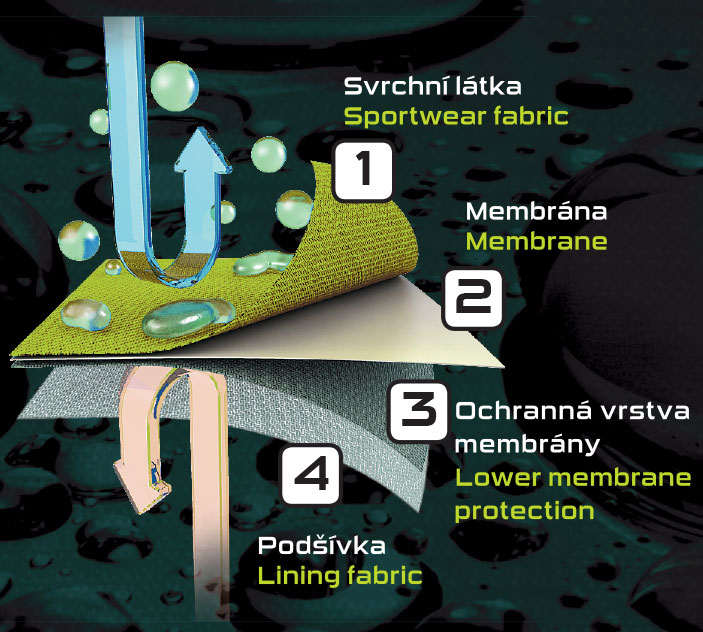

It is a so-called three-layer laminate, where the following three layers are joined by lamination: the upper fabric, the A.C.D. membrane and the lower membrane protection.

The material thus obtained is designed for garments for extreme conditions, it can withstand even higher water pressure, while the vapour permeability remains the same as in a two-layer membrane.

Airysoft is a lightweight, stretchable, breathable material (active shell). This material is very windproof and, although it does not contain a membrane (which makes it highly breathable), it ensures optimum indoor comfort for the wearer.

Airtastic is a trademark of Toray Industries, Inc.

Airtastic fabrics are characterised by their precise and very dense structure, which is woven from extremely fine yarns (maximum 20D fibre diameter), resulting in a series of fabrics whose key features are low weight, good wind resistance thanks to the dense weave, while maintaining very high breathability.

(Body Heat Barrier) is a thermal insulation material that ranks among the top performing extreme use materials on the current outdoor market. BHB Micro is used in Pinguin's top of the range sleeping bag range, replacing the previously used branded materials PrimaLoft® Sport and Polarguard 3D®. The inclusion of BHB Micro in the collection was preceded, among other things, by a series of comparative measurements in an accredited testing laboratory, where BHB Micro showed the highest thermal resistance values among all measured branded insulation materials.

BHB Micro thermal insulation is based on:

- Siliconised ultra-fine microfibres, whose microscopic surface binds a large number of air molecules.

- Excellent loft, which is achieved by combining the microfibres with the structure of thicker hollow fibres. These two aspects prepare the optimal physical conditions for achieving its excellent thermal insulation parameters

BHB Micro is very lightweight, soft, breathable and highly compressible. It is easy to care for, washable and dries very quickly. The siliconised fibres repel water and, thanks to their density, form a barrier that partially protects the wearer against moisture and keeps him dry and warm even in extreme conditions. BHB Micro is a very successful replacement for down, but unlike down, it is very suitable for allergy sufferers.

It combines the advantages of natural feathers, such as excellent thermal insulation, high loft, low weight and high compressibility, together with the benefits of synthetic insulation, such as high insulation performance even in wet weather. In addition, it is also suitable for allergy sufferers.

- Insulates even in wet weather

- Suitable for allergy sufferers

- Insulation performance very similar to 600cuin goose down

- Compressible

- Lightweight

ClimaControl Shield technology provides a balanced outer fabric, prevents warm air from leaking from inside while providing adequate breathability.

Optimizes the ratio between wind resistance to maintain heat and moist to prevent condensation.

A combination of these features provides user comfort and a favorable interior climate of the sleeping bag

The waterrepellent treatment provides sufficient protection against adverse weather conditions.

Fabric with Clima Control Shield finish is lightweight, foldable and soft to the touch.

The Korean company Dong Ah Aluminum Co., known as DAC, is the world's leading manufacturer of high quality tent rods and accessories for use in the most demanding conditions.

For 30 years, DAC has been manufacturing the lightest, strongest and highest quality aluminum products in the industry. They strive to excel in three areas: Innovation, Sustainability and Performance. As a true development partner, DAC works closely with the best tent manufacturers around the world to design and manufacture the lightest and most durable tents.

DAC Featherlite NSL

The NSL Featherlite rods from Korean manufacturer DAC are the best choice if you are looking for strong and lightweight tent rods.

They feature high precision manufacturing, the use of high quality 7001 T6 aluminum and ingeniously designed construction.

Each segment has two different diameters for optimum strength. Each segment is widened at the ends where the segments join, and narrowed in the middle. The advantage of this solution is the weight saving and the fact that the segments and the connecting insert have the same diameter increases the overall stiffness and strength of the members.

DAC Green anodizing

Clean manufacturing processes are extremely important to DAC. They are critical to reducing the environmental impact, ensuring the health and safety of DAC employees and maintaining product quality and tolerances.

DAC has dedicated more than eight years to developing an environmentally friendly anodizing process that eliminates the use of nitric and phosphoric acid from production. Compared to the standard anodizing process used by other manufacturers, this unique anodizing process places minimal burden on the environment.

Dural 7001 T6

Lightweight, very strong and flexible thin-walled rods made of stainless duralumin alloy with a diameter of 8.5 mm, resistant to high loads in the mountains. Precise design and surface finish minimise the risk of punctures.

Dural 7075 T9

The construction of the Extreme series tents is suitable for use in the most difficult expedition conditions thanks to the use of stainless duralloy with a high strength limit (higher than the 7001 T6) and high stiffness due to the larger diameter of thin-walled members (9.5 mm).

Durawrap

The fiberglass rod segments are coated with a reinforcing polyester film that increases strength and flexibility while reducing the possibility of splitting. Protects the rod from mechanical damage.

DWR

(Durable Water Repellent - is a surface treatment that prevents water from penetrating the surface of the fabric and helps prevent the garment from soiling.

A garment with a DWR treatment resists rainwater, droplets roll off and the surface remains unsoaked. After a certain period of use, a spontaneous fading of the DWR effect can be observed, which is further accelerated by, for example, washing in strong chemical detergents. It is therefore recommended to renew the protection after a while with special impregnation sprays.

C6 DWR

It is currently the most effective water-repellent fabric treatment with faster degradation and low environmental impact.

Compared to the widely used C8 treatment in the past, which was very efficient but very poorly biodegradable.

It is a very lightweight material made with a special technology where the functional PU layer on the reverse side of the fabric is so resistant to mechanical damage that it does not need to be protected by a lining. It is designed for the production of lightweight and storable garments that we can always carry with us in case of bad weather.

- Pressure resistance: 10 000mm H2O

- Vapour permeability: 15 000g H2O/m2 za 24h

It is a very versatile material composed of three layers that are bonded together by lamination technology. The outer layer is a mechanically resistant flexible nylon. Thanks to the Gelanots membrane, taped seams and laminated inner layer of microfleece, the Gelanots softshell is 100% water and windproof, highly breathable and thermally insulating.

Softshell jackets that have an insulating fleece layer on the underside cannot be sealed at the seams to make the seams 100% waterproof. This generally applies to all garments made from 3-layer softshell materials, regardless of the brand and membrane used. Most softshell garments from other brands do not have seams taped at all. Gelanots softshell jackets are lined with waterproof tape on the bottom (or top) seams, which can only prevent about 90% of moisture from penetrating. In practice, this means that the jacket is 100% waterproof on the surface, but the tape stuck on the fleece layer (or the top fabric of the laminate) cannot seal the seam so that a certain (relatively small compared to unlined seams) amount of moisture does not escape through the layer between the membrane and the taping after a certain time.

- Pressure resistance: 20 000mm H2O

- Vapour permeability: 20 000g H2O/m2 za 24h

Gelanots XP

It is a unique hydrophilic membrane that is laminated to the textile material of the sportswear. It forms a perfect protection against the weather and at the same time maintains a constant microclimate on the surface of the body at rest even during intense physical exertion. It has been developed for active outdoor sports and its parameters satisfy even the most demanding comfort requirements of the user.

- Pressure resistance: 20 000mm H2O

- Vapour permeability: 20 000g H2O/m2 za 24h

It is a so-called three-layer laminate, where the following three layers are joined by lamination: the top fabric, the Gelanots XP membrane and the lower membrane protection. The material thus achieved is designed for garments for extreme conditions, it can withstand even higher water pressure, while the vapour permeability is maintained as with the XP membrane.

- Pressure resistance: 30 000mm H2O

- Vapour permeability: 20 000g H2O/m2 za 24h

Laminate

Fiberglass rods are made with a new technology that achieves lower segment weight with increased resistance to breakage.

It is a three-layer laminate, a product of the Italian company Pontetorto. It is a combination of an upper microfleece layer, a membrane and a lower perforated protective layer. The result is a 100% windproof, highly vapour permeable, soft, user-friendly material.

It is a flexible, highly durable fabric made from specially treated Nylon fibres, which is used on particularly stressed areas of the garment. Its elastic ability allows an increased range of movement, while the high abrasion resistance of this material (comparable to Cordura) prevents wear and tear on these areas.

Nylon Featherlite RipStop DWR

Very lightweight and strong nylon fabric with RipStop weave and DWR water repellent treatment.

Featherlite RipStop DWR Nylon is a tightly woven, very lightweight and breathable Nylon fabric with a non-wrinkle and waterproof finish. It's the tightly woven fibres that stop even very strong winds, while still allowing your body to breathe freely.

RipStop treatment ensures that if you tear the jacket, it will not continue to pile up, but will stop against one of the regularly placed thicker fibres.

DWR causes any rain to run freely down the material instead of seeping inside the fill.

It is a very comfortable, breathable fabric made of 100% nylon fibers, which are produced with a special technology and treated to the so-called wick effect. This makes them as close as possible to natural fibres in terms of look and feel. The resulting fabric is soft, flowing and pleasant to the touch like natural fibre fabrics, but retains the shape and colour stability, lightness, strength and durability of Nylon. Wicking treated fibre also wicks body moisture away from the skin, unlike natural fibres it is non-absorbent - so it doesn't retain moisture and doesn't shrink, but wicks moisture to the surface to evaporate and the fabric stays dry.

Lightweight and very warm brushed fleece on both sides with antibacterial and excellent insulating properties.

The waterproof design with a DWR finish resists light rain or snow. Polartec Classic 200 is a quick-drying and mechanically highly durable material that is easy to maintain and machine washable.

It is a fleece material for garments with a medium insulation layer that is also highly breathable - thus allowing sweat to be quickly wicked away towards the outer layers of clothing.

Polyester

The lightweight and strong polyester material has high UV resistance, does not age and retains its properties even when exposed to the sun's rays and temperatures for long periods of time.

Polyester DWR

Outer material with water-repellent treatment.

Thanks to the DWR treatment, the fabric is highly non-absorbent and water-repellent, and drops tend to run down it, so it can withstand even a short drizzle or morning dew..

PU coating

The polyurethane coating is a thin waterproof polyurethane layer applied several times on the inside of the tropic. Depending on the number of layers of coating, the water pressure resistance of the tropic is distinguished.For our tents, we apply the technologically available maximum, which reaches a water column of up to 4000mm. The coating retains its elasticity even at very low temperatures well below freezing.

Ripstop

It is a fabric manufacturing technology used in the Extreme Series tropical tents and the Extreme and Hiking Series inner tents to increase resistance to mechanical damage while reducing weight. At regular intervals, thicker fibres are woven crosswise and longitudinally into the material of the canopy to form a grid, which prevents further tears from spreading if the fabric is torn.

Siliconization

On the outer shell of the tent, the silicone treatment achieves a highly effective and timeless water-repellent effect.

In this technological process, the fibres of the fabric are impregnated with silicone, making the fabric extremely water-repellent with self-cleaning properties.

The so-called lotus blossom effect occurs, where water droplets are repelled from the surface of the fleece, water is not retained in the fabric even when it is imperfectly switched off and quickly drains off in the form of droplets, taking all the dirt with it.

Combined with the PU coating on the inside of the fabric, it is currently one of the most sophisticated methods of protection against moisture penetration. Another important effect of siliconisation is a significant increase in the strength, elasticity and tear resistance of the siliconised fibres of the rain fly.

SPANDEX®

It is a synthetic polymer fibre, also known as Elastane or Lycra, developed in 1958 in the laboratories of DuPont.

It is used in the manufacture of technical fabrics where it is blended with other durable materials (Nylon, Polyester). Its excellent elasticity leads to increased comfort and durability of the fabrics in which this fibre is used.

ITW Nexus clips

ITW Nexus branded clips anchor the tent to the tent structure and allow tension control. They are made of tough plastic that is very strong and retains its mechanical properties even at extremely low temperatures.

Fleece material, product of Pontetorto (Italy), for the production of thermal insulation garments.

(výrobce DuPont)

(výrobce DuPont)

It is a special treatment in which the fibres of the fabric are impregnated and treated to achieve a highly water-repellent effect while retaining the original airy, soft and flowing properties of the treated fabric. The manufacturer guarantees that the water repellent effect will not drop below 50% of the original level even after 40 washing cycles.

It is a softshell material - a three-layer laminate where the outer layer is a flexible nylon fabric, the membrane and the third (bottom) layer is a thermo-insulating microfleece. It combines the advantages of fleece and membrane materials (high vapour permeability, 100% windproof) and the mechanical resistance of the outer nylon fabric.

- Pressure resistance 10 000mm H2O

- Vapour permeability: 10 000g H2O/m2 za 24h

The insulating function of the fleece achieves the performance of wool while offering excellent breathability and partial wind resistance. The main advantages of fleece are:

- Relatively lightweight compared to wool

- Pleasantly soft, without scratching

- Dries quickly

- High breathability

- Easy to maintain, machine washable and tumble dry

- Always insulates, even when wet

Thermicore Classic can be used as an outer layer for less demanding conditions or as an ideal mid-layer between underwear and an outer windproof or waterproof jacket.

THERMICFIBRE PFM is a new generation thermal insulation material consisting of a mixture of siliconized hollow fibers with a very small diameter comparable to microfiber.

The high thermal resistance of the fibers results from the ability to bind large quantities of air molecules not only inside the cavity, but also on the surface of the fibers due to the microdiameter.

Siliconization of the surface fixes the fibers in their mutual position, thus achieving the effect of a spring - a high loft of the thermal insulation layer, at low weight and excellent packability.

Thermicfibre PFM is a non absorbent material with a water repellent finish, dries quickly, insulates perfectly even in high air humidity, is absolutely non allergic, very soft and user friendly.

Easy to maintain, machine washable and machine dryable.

Single-layer insulation | Double-layer insulation | Shingle insulation | Triple-layer insulation

Toray Industries, Inc. Founded in 1926 in Japan as a silk thread manufacturing company.

Since then, the company has been dedicated to the development of new fibers for technical fabrics.

Over time, Toray has expanded its operations to 26 countries and continues to develop high-performance fiber applications in regions around the world for high value-added products created in the manufacturing core, which is still Japan.

In addition to the goal of producing high-end fibers and their applications, Toray also places great emphasis on social responsibility and environmental protection:

"Since our founding, we have considered 'contributing to communities' as the foundation of our existence, and in 1955 we established this as a corporate principle.

This idea is reflected in our corporate philosophy of Contributing to society by creating new value with innovative ideas, technologies and products, formulated in 1986, and also in the Toray Group's Sustainability Vision, which we formulated in July 2018.

Going forward, we will continue to place great emphasis on our social responsibility at the Toray Group and consider safety, accident prevention and environmental protection and corporate ethics and regulatory compliance"as top management priorities.

By offering products and services that benefit society, we hope to meet the expectations of our stakeholders."

Zippers from a renowned Japanese manufacturer, which are among the best produced in the world in this field.

Zippers of this brand guarantee quality, durability and reliability. Components of small size but of great importance, because their trouble-free functionality is usually a prerequisite for the function and usability of the entire product.

It is a special waterproof zipper design for waterproof clothing.

Korea Yunan Aluminum Co., LTD was founded in 1979 and has quickly become one of the leaders in the aluminum tube processing industry.

Yunan uses high quality 7001 T6 aluminum alloy to produce outdoor products such as tent poles, hiking and golf clubs.

As a result of its efforts to meet the diverse needs of its customers through the use of state-of-the-art technology, experience and the introduction of new technologies in the production of aluminium products, Yunan's products are included in the portfolio of many Hi-end outdoor brands.